Simply makes you

feel good

Converting solutions for the tissue and hygiene industry

Winkler+Dünnebier GmbH (W+D) and Paper Converting Machine Company (PCMC) are part of global equipment manufacturer Barry-Wehmiller and its BW Converting Solutions (BWCS) platform.

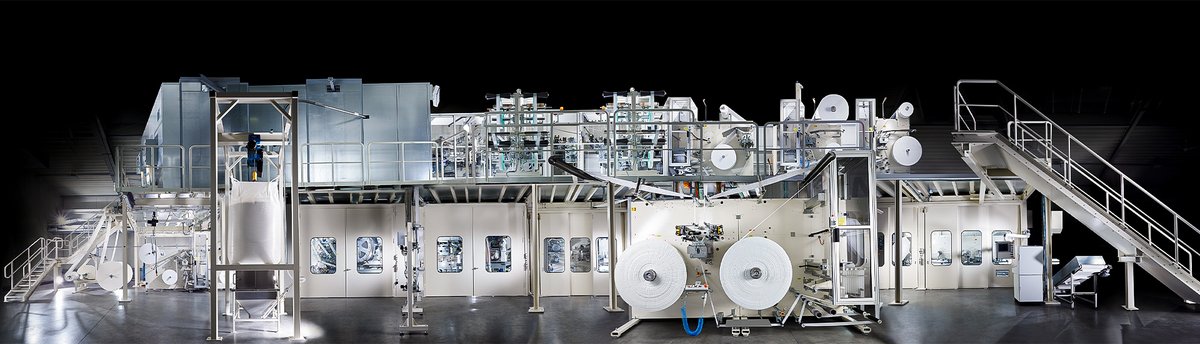

Together, these two companies represent the hygiene sector of the BWCS platform and offer a wide range of high-performance machines and services to the hygiene industry worldwide. The comprehensive product offerings include converting lines for Baby Care, Feminine Care, Adult Care, Dry and Wet Wipes, Tissue Handkerchiefs, Facial Tissue, and Face Masks.

Simply feeling good and comfortable is a basic human desire. In everyday life, disposable hygiene products are key to the experience of well-being. We invest all our know-how and resources in developing excellent technology for our customers to manufacture personal care and tissue products of the highest quality and with innovative product features, whilst obtaining economical and efficient production conditions.

W+D Hygiene Solutions is a merger of the German machine manufacturing companies BICMA Hygiene Technologie GmbH and Winkler+Dünnebier GmbH (W+D). They joined expertise of more than 40 years in hygiene converting resources in 2018 with the aim to provide even better products and optimized customer service. W+D’s core competencies encompass converting and precise processing of thin and inhomogeneous materials at high production speeds, for example paper, tissue, and nonwoven materials. The company designs and builds top-quality, customized machinery and retrofits. It is a partner of manufacturers of baby diapers and pants, feminine hygiene products, light incontinence products, adult diapers and pants, handkerchiefs, facial tissue, face masks as well as underpads.

Paper Converting Machine Company is a leader in tissue converting, packaging, flexographic printing, and bag and wipes converting technology — backed by a century of machine design, manufacturing, and service experience. With four major production centers in the U.S., England, Italy, and Serbia, and 1,000 team members worldwide, PCMC is uniquely equipped to provide customers with a broad range of automated converting solutions.

Standing behind all of our equipment is our promise to serve you and service the machines that you rely on to keep your business moving.

There is more to a company than its name and history. It is the people who make the difference.

Flexibility

Flexibility has been part of our DNA for decades, resulting in tailor-made customer solutions and flexible machine concepts. Our machines are known to be among the fastest in format change thanks to our quick-change mod- ules or our express drum-change technology.

Innovation

Innovation drives us day by day to create smart and extraordinary solutions relating to products and processes. With our lab lines we are able to develop with our customers the products for tomorrow.

Competence

Competence accrued in the hygiene industry over decades makes every member of our team a reliable partner for our customers.

Sustainability

Sustainability of the machines we build and of the products manufactured by using them has inspired our activities right from the start. Reduced energy consumption, zero-waste processes, glueless bonding, and replacing single-wrap plastic by paper material are important parts of our philosophy.

There is more to a company than its name and history. It is the people who make the difference.

Flexibility has been part of our DNA for decades, resulting in tailor-made customer solutions and flexible machine concepts. Our machines are known to be among the fastest in format change thanks to our quick-change mod- ules or our express drum-change technology.

Innovation drives us day by day to create smart and extraordinary solutions relating to products and processes. With our lab lines we are able to develop with our customers the products for tomorrow.

Competence accrued in the hygiene industry over decades makes every member of our team a reliable partner for our customers.

Sustainability of the machines we build and of the products manufactured by using them has inspired our activities right from the start. Reduced energy consumption, zero-waste processes, glueless bonding, and replacing single-wrap plastic by paper material are important parts of our philosophy.

W+D Hygiene Solutions

Company brochure

You can find out more about our technology, product, and service offerings in our image brochure.

![[Translate to Englisch:] reffen Sie uns in Berlin auf der GO Wipes Europe](/fileadmin/_processed_/3/b/csm_news-W_D-messe-go-wipes-DE_02fc3f7826.png)